The importance of screening in sand and gravel production

Screening is an essential link in the sand and gravel aggregate production line. The purpose of screening is mainly to separate materials with different properties.

Types of screening machinery

Most of the screening machinery uses rotation, vibration, reciprocating, shaking and other actions to separate the materials through the screen into several grades according to the particle size of the materials.

Screening machinery is divided into the following types according to their structure and movement characteristics. Different screens have their own advantages and scope of application when processing materials.

Introduction to different vibrating screens

Circular vibrating screens and linear vibrating screens are commonly used in mining production. Let’s take a look at the characteristics of these screening machines in small mining belts.

01 circular vibrating screen

The circular vibrating screen uses the centrifugal force generated by the rotation of the eccentric block in the vibrator to force the screen box, vibrator and other parts to perform forced continuous circular or approximately circular motion.

It has the characteristics of reliable structure, high screening efficiency, strong excitation force, durability, convenient maintenance and safe use.

Widely used in mining, building materials, transportation, energy, chemical industry and other industries.

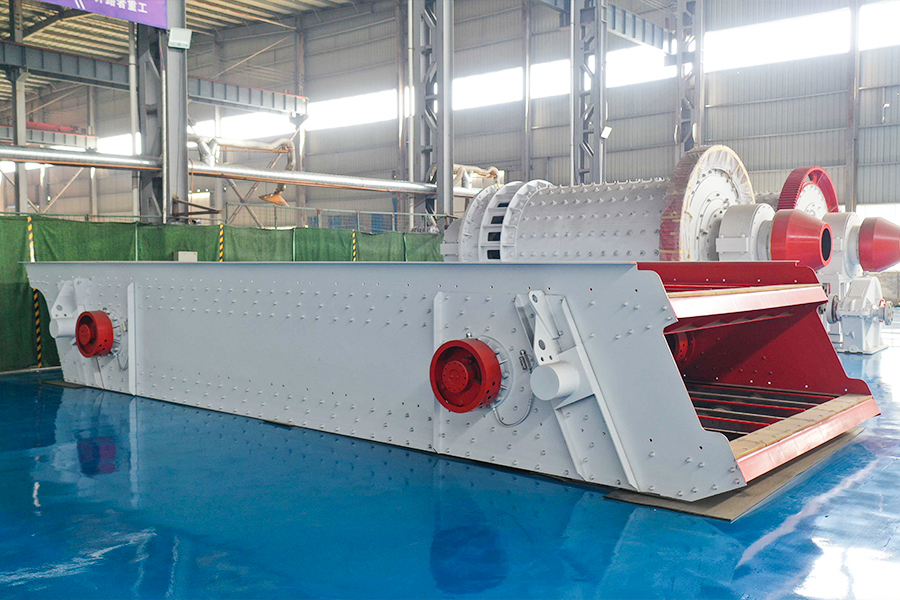

02 Linear vibrating screen

The linear vibrating screen uses the vibration motor to excite the force, so that the materials are thrown up on the screen and move forward in a straight line.

The vibration parameters are reasonable, the movement is smooth, the energy consumption is low, the output is high, and the screening and dewatering efficiency is high.

Fully enclosed structure, no dust spillage, automatic discharge, more suitable for assembly line operations.

03 Resonance screen

Resonance screen is a vibrating screen in which the vibration frequency of the screen surface is consistent with the natural vibration frequency of the screen surface (including the loaded materials).

It can effectively utilize the natural frequency of the equipment and work in a state close to resonant vibration, so it consumes very little power.

The structure is relatively complex, adjustment is troublesome, the failure rate is high, and there are many problems in terms of structural strength.

04 fixed screen

The working part of the fixed screen is fixed, and the screening of materials relies on the materials sliding along the working surface under the action of their own weight.

It has a simple structure and is easy to manufacture. It consumes no power and can directly unload the ore onto the screen surface, thus saving costs.

It is widely used in mineral processing plants, but has low productivity and low screening efficiency. It is mainly used for pre-screening before coarse or medium crushing.

05 roller screen

There are plates on the roller screen shaft. Fine materials pass through the gap between the rollers or plates. Large materials are driven by the rollers to move to one end and discharged from the end.

Materials running at two different speeds start to move axially when they meet at a certain position on the screen surface, thereby achieving the purpose of improving screening efficiency.

Roller screens are rarely used in mineral processing plants.

06 equal thickness sieve

The principle of equal thickness screen is an efficient screening technology developed based on the theory of material group movement on the screen surface.

During the screening process, the thickness of the material layer on the screen surface remains constant or increases.

The equal thickness screening method can exponentially increase the processing capacity of the screen machine.(xingaonai)

Statement: If the content on this site infringes upon the legitimate rights and interests of the original author, please contact this site to delete it.